Palletizing Solutions

IMS Group USA delivers advanced palletizing systems designed to improve efficiency, safety, and flexibility across industries. Whether you need a high-speed, high-capacity solution or a compact, collaborative system, our palletizers are engineered to handle bags, boxes, and bundles with precision.

Layer Palletizers

Layer Palletizer: High-Level Feeding

Our HF Series Layer Palletizer is designed for high-speed production in demanding environments. This robust machine features mobile pallet and top bag loading for efficient operation.

Features:

-

High-speed performance, handling up to 2,800 bags per hour

-

Easily adjust to different bag sizes and pallet layouts with 20 programmable patterns

-

User-friendly, intuitive software and minimal operator intervention

-

Inverter-controlled, belt-driven system for quiet and efficient operation

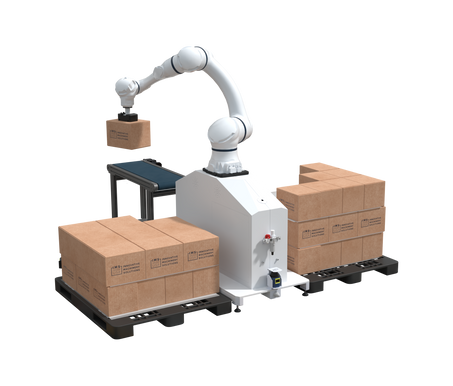

Robotic Palletizers

Robotic Arm Palletizers

Our Robotic Arm Palletizer delivers efficient and flexible palletizing for boxes, bundles, and bags. This advanced system can handle up to four product lines simultaneously using a single robotic arm.

Features:

-

Versatile product handling, accurately recognizes and sorts products onto designated pallets

-

Compact design with seamless integration into existing packaging lines

-

Easily adjust picking heads for various package types, including pallet, slip sheet, and top sheet placement

-

Efficiently palletizes multiple product lines simultaneously

Collaborative Robotic Palletizers

RO-PAL

HC Series Collaborative Palletizers

Designed to work independently or alongside human workers, RO-PAL is a compact, collaborative robotic palletizing system designed for safe, flexible, and efficient operation. This system combines advanced safety technology and intelligent software to deliver reliable palletizing with a minimal footprint.

Features:

-

Collaborative design with laser safety zones for barrier-free operation

-

Dual-position reach for max throughput with minimum footprint

-

Compact and scalable for easy integration into existing lines

-

Intuitive touchscreen controls for fast setup and operation

-

Easy hand-guided teaching for fast setup and changeovers.

-

Six-axis flexibility for versatile packaging and end-of-line tasks

-

IP67 all-axis protection for tough industrial environments