top of page

NEWS AND UPDATES

Out with the Bagging Line — New Shrink Wrapping Solutions Move Into the IMS Showroom

Change is happening in our Grand Rapids showroom. Our previous bagging line equipment has officially been moved out to make room for the next wave of packaging innovation. As IMS continues expanding the solutions we offer, we’re excited to introduce two advanced shrink-wrapping systems now available for live demonstrations and customer trials. These additions strengthen our ability to support manufacturers looking for flexible, efficient, and high-performance packaging soluti

4 hours ago2 min read

IMS Group USA Earns 2025 Avetta Safety Star Recognition

IMS Group USA has been awarded the 2025 Avetta Safety Star in recognition of our commitment to safety excellence and compliance. This achievement reflects the accountability, teamwork, and disciplined safety practices upheld across our organization. Through consistent training, strong oversight, and trusted partnerships, IMS continues to prioritize a culture where safety is embedded in everything we do.

Feb 91 min read

Packaging Films Designed to Maximize Machine Performance

High-quality packaging film plays a critical role in protecting products, optimizing machine performance, and reducing downtime. IMS offers a full range of packaging films—from FFS and technical films to stretch hood solutions—designed for durability, efficiency, and sustainability. Backed by IMS’s Film & Service Program, our solutions go beyond film to deliver consistent performance, expert support, and long-term value.

Jan 192 min read

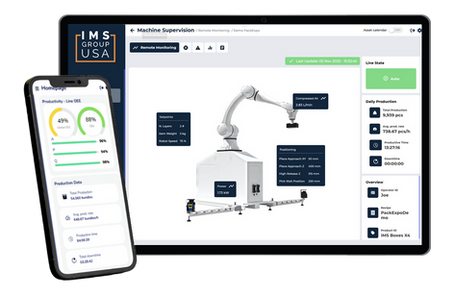

Showroom Spotlight Series: Machine Analytics Tool (MAT)

Real-Time Visibility for Modern Production MAT delivers comprehensive production visibility by combining real-time monitoring, detailed machine data recording, and intuitive performance analysis. It empowers you to quickly identify downtime causes, track quality and scrap trends, and optimize scheduling—all through clear reports and integrated audio/video insights for smarter, more efficient operations. Real-Time Machine Monitoring Monitor your plant in real time with a 3D di

Dec 29, 20255 min read

bottom of page