Stretch Hood Machines

Utilizes the elasticity of tubular plastic film, stretched and released around the pallet load, leveraging vertical and transverse forces to achieve maximum stability without the need for heat.

Enhanced Protection: Secure, UV-resistant, and waterproof coverage with exceptional clarity for product visibility. The film can also be printed with product branding.

Integration Options: Integrates with business software through a user-friendly HMI. Additional features include remote access profiles, a simple hooding control cycle, real-time diagnostics, and backup on portable drives.

Stretch Hooder - Starstretch FB 4.0

The Starstretch FB4.0 is the latest innovation in stretch hooding technology, offering a versatile solution that automatically recognizes and accommodates multiple pallet and film sizes, and ensuring efficient, sustainable pallet hooding with a professional appearance.

FEATURES

-

Speed: 280 pallets per hour

-

Minimum pallet size: 400 × 400 mm

-

Automatic pallet size detection

-

Blades and sealing bar may be lowered to ground level

-

Film change over at ground level

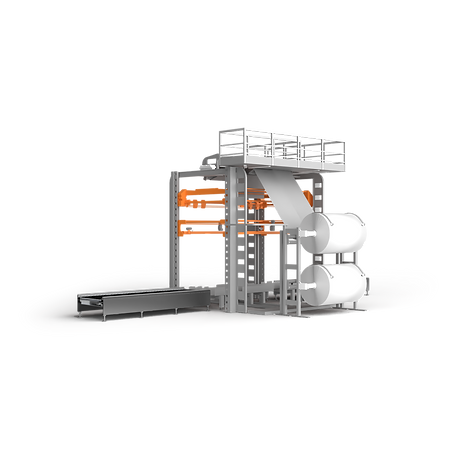

Stretch Hooder - FB2000

The FB2000 hooding machine range is specifically designed for the most challenging production cycles and packaging requirements.

The FB2000 has a hooding capacity as fast as 280+ pallets per hour depending on the load size. A wide variety of machine models allows you to find the ideal solution based on your specific production rates and packaging requirements.

FEATURES

-

Speed of up to 280 pallets/hour

-

Minimum pallet size: 500×400 mm

-

Maximum pallet size: 3600×1700 mm

Stretch Hooder - FB3000

Designed for flexible packaging, utilizing an integrated Cartesian system to handle a wide variety of load shapes and sizes.

Innovative Maintenance System: The patented head lowering system allows all maintenance and operations to be completed at floor level. Operators can lower the cutting edge and sealing bar or the film change station separately for maximum safety.

Features:

-

Speed: 280 pallets per hour

-

Automatic pallet size detection

-

Blades and sealing bar may be lowered to ground level

-

Film change over at ground level

In-Box Bagmaker

A simple solution that automatically inserts tailored bags inside a variety of boxes. This machine automatically unwinds the tubular film from the configurated reel. Four pliers open the film in a square shape, and a sealing bar cuts the film at the desired height to create the tailored bag. An aspirator lays the bag on the bottom of the box and the pliers ensure the bag fits perfectly inside the box.

Features:

-

Speed: up to 60 boxes per hour

-

Can be configured with up to 3 different film sizes

Compatible with:

-

Octabins

-

Goodpack

-

Wooden boxes

-

Cardboard boxes

-

Metal cages