Out with the Bagging Line — New Shrink Wrapping Solutions Move Into the IMS Showroom

- info2636801

- 6 hours ago

- 2 min read

Change is happening in our Grand Rapids showroom.

Our previous bagging line equipment has officially been moved out to make room for the next wave of packaging innovation. As IMS continues expanding the solutions we offer, we’re excited to introduce two advanced shrink-wrapping systems now available for live demonstrations and customer trials.

These additions strengthen our ability to support manufacturers looking for flexible, efficient, and high-performance packaging solutions.

IS 600 BM Automatic Shrink Wrapper

Designed for speed, adaptability, and intelligent automation, the IS 600 BM delivers reliable, high-quality shrink wrapping for small to medium products.

This system supports both continuous and box-motion sealing, providing flexibility across various product types and film materials. Whether packaging individual items or multi-packs, it produces excellent hermetic seals that protect product integrity and enhance presentation.

With speeds ranging from 70–120 packs per minute, the IS 600 BM maintains high output while operating with reduced energy consumption. It is also compatible with ecological and recyclable films, supporting sustainable packaging initiatives.

Key Benefits:

Continuous or box-motion sealing options

Excellent hermetic seal performance

Eco-friendly and recyclable film compatibility

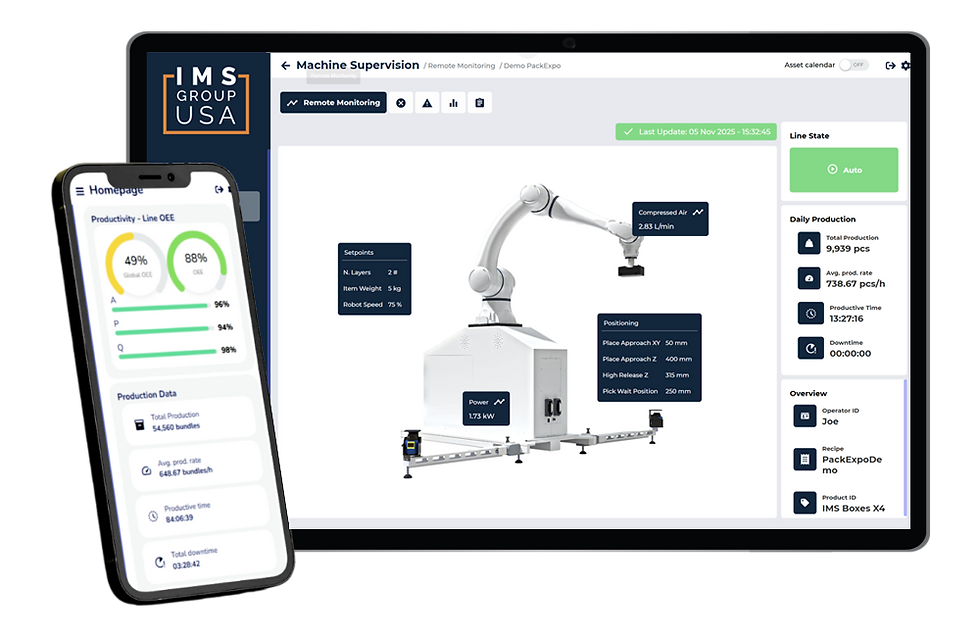

Industry 4.0 connectivity for real-time monitoring

Electronic format changeovers with stored recipes

Integration-ready for labeling, printing, and product handling systems

Engineered for modern automated production lines, the IS 600 BM provides both performance and flexibility in a compact, efficient footprint.

Hammer 600 L-Sealer and Shrink Tunnel

Also now featured in our showroom is the Hammer 600 L-Sealer and Shrink Tunnel — a compact, versatile solution ideal for small to medium solid products.

The system uses precise angle sealing technology to create clean, professional seals across a variety of materials, including PE, PP, bio-films, and paper-based films. With output up to 3,700 packs per hour, it delivers consistent productivity without sacrificing quality.

Its modular design allows it to operate as a standalone L-sealer or as part of a complete shrink-wrapping system with tunnel integration, offering flexibility for evolving production needs.

Key Benefits:

High-quality hermetic seals

Handles a wide range of sustainable film materials

Speeds up to 3,700 packs per hour

Fast electronic format changeovers

Energy-efficient operation

Customizable electronic systems (Allen Bradley or Siemens options)

The Hammer 600 is an excellent solution for companies seeking professional packaging finishes with adaptable configuration options.

Experience the Equipment in Action

At IMS, we believe seeing equipment operate in a real-world setting makes all the difference. With these new systems now installed in our Grand Rapids showroom, customers can:

Schedule live demonstrations

Test products and film materials

Explore integration possibilities

Evaluate performance before investing

As we continue evolving our showroom capabilities, our goal remains the same: delivering tailored, efficient packaging solutions that help manufacturers improve productivity and performance.

If you’re exploring shrink-wrapping solutions or planning an upgrade to your packaging line, we invite you to visit and see what’s new.

Book a Live Demo to see these machines in action, or schedule a virtual meeting with us to learn more.